Improvements are always good for new opportunities and setting better goals. Value Stream Mapping is one way to do it.

Most of us might have heard of this term but won’t know what it is. This blog explains everything you need to know about value stream mapping and its benefits for your organization.

What Is Value Stream Mapping?

Value stream mapping is one of the pillars of lean management and can be described as,

“A method that allows one to visualize, analyze and improve all the steps from the current state to the designing of the future state.”

It is also known as ‘material and information-flow mapping’. It is one of the most pivotal methods for a company that aims to achieve better outcomes. Thus, it improves all the steps included in a product delivery process.

History Of Value Stream Mapping (VSM)

Value stream mapping became a popular concept in the second half of the 20th century with the rise of lean methodology. However, it was originally developed in the Toyota Production System back in the 40s with a different name.

Over time, VSM became a part of many business organizations and outgrew itself from the manufacturing industry. Its popularity got spread to many sectors including IT, marketing, software development, and many others.

What Is The Importance Of Value Stream Mapping?

Value stream mapping is pivotal to maximizing value for the customers and the business. It aims to achieve this by minimizing waste and inefficiencies. Thus, businesses need to stay competitive by managing their resources better and providing more value to the customers along the way.

What Are The Benefits Of Value Stream Mapping?

In addition to maximizing customer and business value, VSM encompasses several other benefits as well. Some of them are:

- It helps to improve processes by identifying the bottlenecks

- Brings out a bigger picture of all the processes

- Identify waste and its sources

- Helps to provide a better customer experience

- Helps businesses to achieve their goals better

- Saves costs by reducing repetitive or inefficient processes

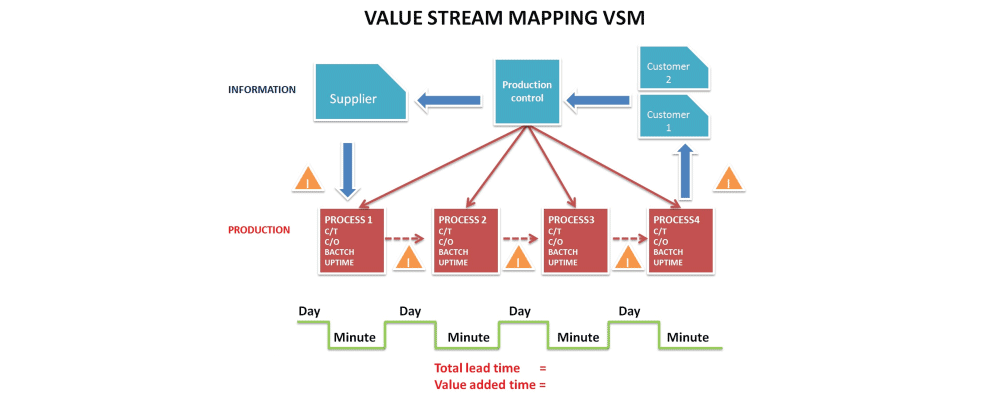

Example Of Value Stream Mapping

Value stream mapping brings out two important scenarios that aid to improve the processes i.e, the current and the future state. The current state will depict how your processes are at the moment and the future state will depict the goal that is to be achieved. However, with the achievement of each process, the future state becomes the current state, creating more room for improvement.

The image is an example of what a value stream map looks like. The structure and elements might change according to the process and business type. However, this is just an example for you to understand or get a hint on value stream mapping.

What Are The Elements Of Value Stream Mapping?

Below are some elements that make up the value stream mapping:

1. Information Flow

It contains all the information relevant to the development of the processes. For example, the activities’ details, the responsible person’s name, and all the essential resources required to complete a task.

2. Process Flow

It is the visual representation of all the processes involved. It identifies all the tasks and activities involved in the development process and defines a proper route for all of them.

3. Lead Time

Lead time is the time that each activity or item takes to move on to the next step. Thus, it includes the idle or on-hold time of each item.

4. Cycle Time

The amount of time taken to complete a task excluding the on-hold time.

5. Percent C&A

The percentage of time the outcomes of the process is successful and require no rework.

6. Takt Time

Takt time is the total time the process requires divided by customer demand. It is easier to calculate when it comes to structured processes that follow the same pattern. However, it is hard to maintain it where there are inconsistent patterns or processes.

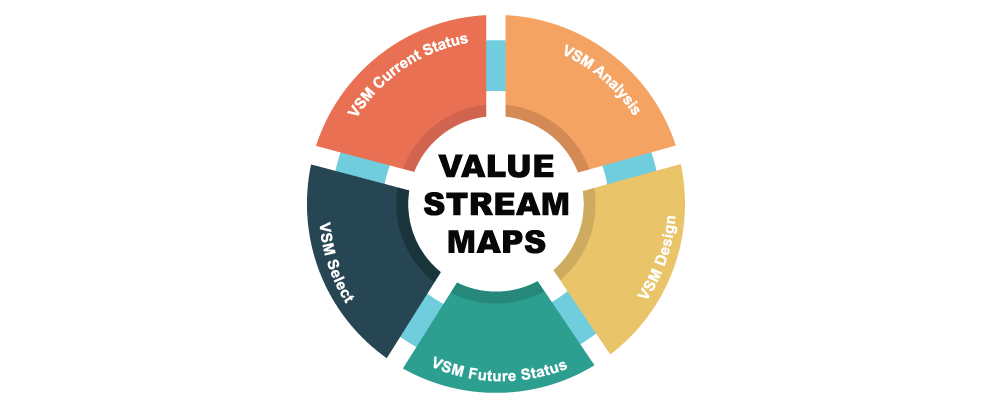

How To Create A Value Stream Map?

Now that we’re aware of the elements involved in value stream mapping let’s understand how to create a value stream map in the current and future state.

It should be remembered that the value stream map for the current state would highlight the bottlenecks and waste that is to be eliminated.

Map For The Current State

The following six steps must be followed for value stream mapping of the current state.

Step:1 Selection of the process to be mapped

This is the initial step in VSM. In this step, the financial managers and other executives oversee the request that is sent by the team. The request that aligns with the business’s goals is then approved and put forward for action.

Step:2 Designate the people responsible for each task

The next step is identifying the driving force for the project. Designate the people involved in the project like a financial manager, supplier, procurement manager, project manager, area manager or general manager, etc.

Step: 3 Breakdown and define each task

Hold a face-to-face or video call meeting to explain each task and process in detail to the people involved. This step is necessary for removing any ambiguities and increasing transparency. Moreover, team collaboration can also lead to the involvement of new ideas and better processes.

Step: 4 Calculate metrics

Calculating metrics and having rough estimations are always beneficial for predicting the future and finding room for improvement. Certain metrics must be calculated like lead time, cycle time, and the percentage of C&A. Such calculations are vital for pinpointing the bottlenecks and reducing waste.

Step: 5 Sketch the value stream

All the processes are drawn in the form of a value stream framework. This visualization is essential to optimize your processes and bring improvements wherever needed.

Step: 6 Analyze

So, once you’ve drawn out the whole plan, you must stand back and analyze it. Carefully assess if it works or not. If the processes don’t seem to work out, don’t hesitate to redraw them.

Try out different templates and keep reworking them with the team involved until the processes are improved.

Now that you have the map for the current state, it’s time to predict the future state.

Map For The Future State

Mapping for the future state helps to analyze where you want to reach with the processes mentioned in the current state. So, keenly observe the areas for waste, bottlenecks, and waste to optimize your processes.

The following steps are involved in mapping for the future state:

Step:1 Highlight the processes that need to be improved

Find out what’s causing the delays and repetition and how they can be improved. In this step, identify the areas or processes that need to be improved. Moreover, also pinpoint the bottlenecks and waste hindering the processes.

Step:2 Define how to utilize the tools and resources

Map out and explain to the whole team where the processes in the current state got delayed or faced bottlenecks. Explain the usage of all the tools and resources in detail to avoid such occurrences in the future.

Step: 3 Map it out

The last step is to map it all out. Analyze if the processes have been improved and optimized to reach the set goals or not. Record where the processes had lacked in the current state for future reference.

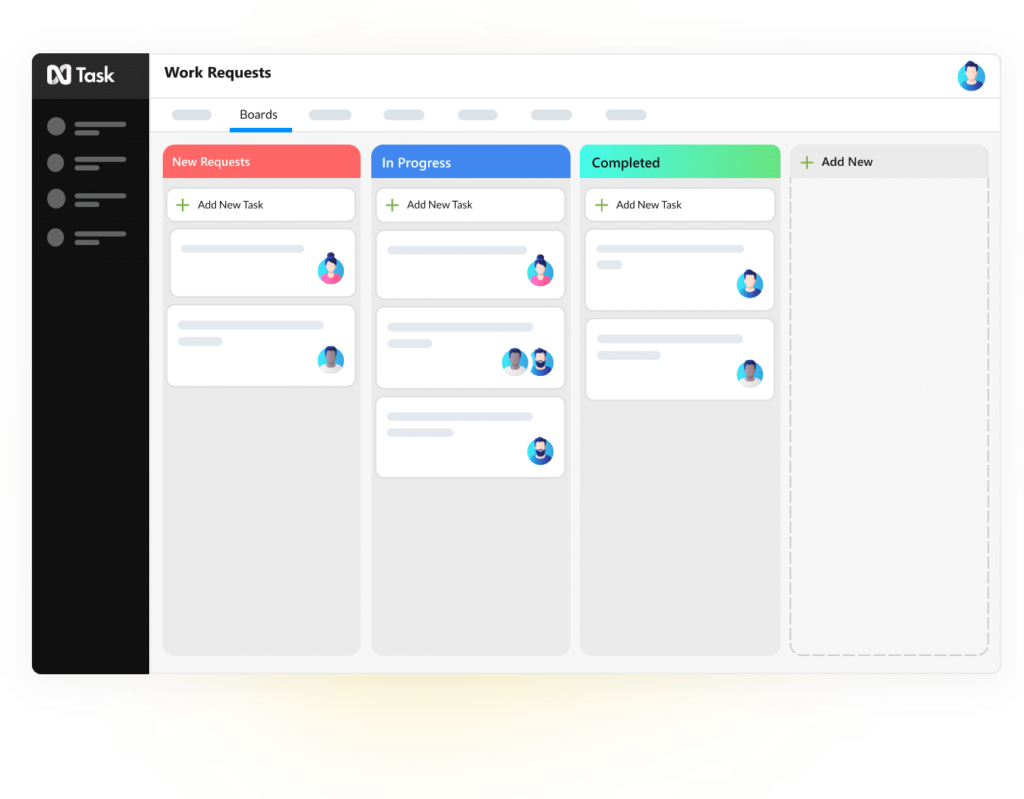

Value Stream Mapping with Kanban

Most of the project management software like nTask features a Kanban board. You can work under one space and optimize the processes as well.

Moreover, Kanban boards are great for gaining effective visualization, spotting bottlenecks, and reducing repetitive processes. You can record time spent on each task and bring the necessary improvements.

Here are a few steps that you can follow to value-stream your processes with a Kanban board.

1. Identify the size of your value stream map

Don’t go for elaborate maps with plenty of steps. Take it to step by step. Identify and solve one-step first and then move on to the next one.

2. Identify the problem and work out on it

Work out the problem that needs to be solved. Whether it is the cost, quality, or production speed.

Define it and discuss it with the team to give them an idea of what they should work on.

3. Pinpoint its advantages

To get the whole team and executives on board in solving the problem, pinpoint its benefits to them. Let them know how value stream mapping would help to improve the processes and benefit the whole company in the long run. So, bring out some facts to get everyone on board.

4. Select the tools

Since we are using project management software like nTask to implement this VSM, explain how it works to the team. Once you know all the specifics, you’re good to create a Kanban board for the problem at hand.

5. Create a Kanban Board

Kanban boards have three or more work states. These include:

- To be done

- To do

- Current

- In progress

- Canceled

- Completed

Record all the processes, especially the ones in the progress stage. Calculate the time taken at each process and the bottlenecks faced. This will help you to prepare a detailed report and you won’t miss out on anything.

6. Record and create metrics

Record all the processes and identify some performance metrics to effectively improve all your operations. Such metrics would help you to analyze your current state and bring practical improvements for the future.

These metrics include cycle time, lead time, repetitive steps, number of tasks, time is taken, etc.

7. Create a workflow

Create a new workflow and ensure it aligns with your company’s objectives.

8. Implement your workflow

The last step is to implement your map and analyze it carefully. Monitor it closely to keep it aligned and flowing as planned.

Moreover, stay agile and adapt to changes as they might come along the way.

To wrap it up!

Continuous improvement and optimization of the processes are vital to reaching the desired results. You must split up the processes to effectively analyze each state and improve it. The streamlining of the processes ensures that the project is getting executed successfully.

However, the improvement in processes is a never-ending process. When you reach your future state, it automatically becomes your current state. So, the more you improve, the better the results you’ll gain.

Therefore, the need to have a value stream mapping process is vital for every organization.