No business becomes a success overnight, but with a process improvement plan, your business can be that much closer to where you want it to be.

A process improvement plan is a proactive approach that seeks to find the weak processes within your established processes. It is a documented strategy for improvement.

Before you get started on your process improvement plan it might be useful to look into process improvement methodologies you could adopt. There are a bunch of methodologies you can choose from but below are three commonly adopted ones.

Commonly Used Process Improvement Plan(s)

These methodologies are not a ‘means to an end’. Since technology is the fastest evolving platform all over the world these days, take the appended process improvement plan(s) as a general guideline.

Improvise as a project manager as your team moves forward.

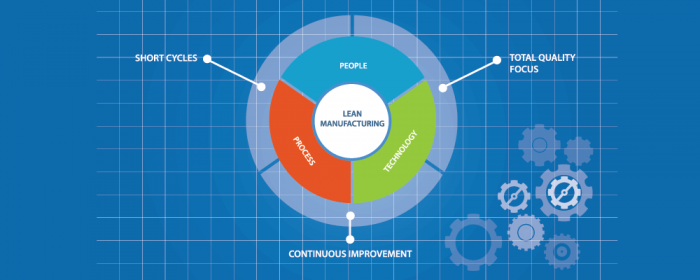

1. Lean Manufacturing

Lean Manufacturing aims to improve product quality and maximize quality output. This is achieved by eliminating 7 wastes. These wastes include:

- Overproduction

- Transportation

- Motion

- Waiting

- Over-processing

- Inventory

- Defects

2. Six Sigma

Six Sigma is a set of techniques and tools that help with process improvement. Six Sigma works by decreasing the probability that a defect will occur.

3. Business Process Management

Business process management applies continuous improvement. Adopting the business process management methodology requires a company to:

- Analyze

- Redesign

- Execute

- Monitor

- Optimize their processes

No matter which methodology you choose, creating a process improvement plan can help you to adapt in a way that improves your overall outcome.

Any attempts to improve your business can quickly be forgotten or overlooked, for any such attempts to stick, it is essential to implement a process improvement plan. Now let’s see just how you can get started with that.

Below is a concise guide on how you can start with your plan and tips and tricks you can use to make the whole process easier. We will also discuss how to go about each step to be able to implement your plan with success.

6 Steps to Deploying a Process Improvement Plan

Step 1: Recognize

Before you plan on improving your business processes it is essential to know where you need that improvement.

The first step is to pinpoint the process that needs improvement. You might want to lay out the different steps to that particular process to see how it is being performed at present, this will allow it to be easier to pinpoint the exact areas that need improvement.

You may find it beneficial to recognize one priority area that is in desperate need of improvement. Perhaps the process takes more time than is productive, or maybe it’s just the attitude towards the process that is letting your business down.

When starting with any improvement plan it might be better to start with something specific but simple.

The vaguer or more complicated the issue, the more difficult the solution can be. Moreover, sometimes a major blockage can be greatly impacted and improved by the change of the simplest thing.

Furthermore, the easier the implementation of the change, the quicker results can be seen and it always boosts morale and inspires people to do more to fix issues if they have a win under their belt straight away.

Step 2: Analyze & Identify

Once you have recognized which area in the process you’ve prioritized, you need to take time to analyze it in detail.

You need to trace the problem to its source. In order to amend the problem, you need to determine the precise part of the process that is causing the problem. Only once this is understood can you start to fix the issue present.

Tip: An easy way to achieve this is when you are recognizing the issue and looking through the steps of the process make a flow chart or diagram (click the link for samples). With a visual aid of the process as a whole, it will be easy to see where and how corrections can be made.

Step 3: Re-Design

After recognizing and analyzing the problem at hand it is time to fix it. The analysis should have provided you with the exact issue and how to amend it. It is now time to redesign the steps you take for that particular process and remove the issue.

It is vital here that if your team has not been involved in the process improvement, they are at least brought on board now. The main reason for the failure of process improvement is that teams are not brought on board early enough.

It is human nature to want to stick with the way you have been doing things all along. So, ensure that people are involved in the process to make the implementation of the new design all the simpler.

Furthermore, you will need your team members to help make the change happen. Who is the change going to impact? You’ll probably require help in getting the process underway. Here the flowcharts and diagrams you created can be used to help explain the process to those you are informing.

To redesign the process, you may need the help of those team members. You can get together and brainstorm ideas as to how you are going to solve the problem and redesign the process.

When thinking of the redesign of the process you need to consider each element and whether the solution proposed is the best fit. Remember to contemplate how the redesign would be implemented as well as the risks that can result from the proposed changes.

Step 4: Implement

Once the course of action has been identified it is now time to create an implementation plan. Identify what each member of your team will be working on and how to achieve the most efficient way of implementing your redesign.

Moreover, be sure to create deadlines and timelines for your team. Setting goals and when to achieve them will ensure your process improvement plan is carried out properly.

Furthermore, ensure your plan to implement the redesign is as detailed and clear as can be. The clearer everything is mapped out and identified the easier it’ll be for the team members involved to follow the required changes and steps.

This part of the whole process is where the changes become real and you need to make sure that you stick to your guns and see it through. It might seem overwhelming and tricky to start with but the business functionality will benefit in the long run.

Step 5: Communicate

We have mentioned this in both steps 3 and 4, but communication, really, is the key. Even with your team being part of the analyzing and redesigning aspects of the plan it is essential to communicate the implementation plan in detail with those involved.

“One of the most common ways to overcome resistance to change is to educate people about it beforehand. Communication of ideas helps people see the need for and the logic of a change. The education process can involve one-on-one discussions, presentations to groups, or memos and reports.”

– John P. Kotter

Before any of your plans can be executed to ensure that each step and changes are discussed with all those it will affect or those who will be a part of implementing the redesign.

To carry out the plan they need to know just how that will happen.

Additionally, as mentioned, humans are resistant to change. If your team is clued in from the start about the changes to come and are kept in the loop it is less likely they will oppose it.

After all this planning it is finally time to execute. Make sure you keep consulting your plan and follow through with all the steps you need to make the process improvements.

Step 6: Monitor and Review

You will eventually start to see your plan come to life.

However, process improvement is a constant and evolving task. You can’t expect to execute one plan to improve your business’ processes and think your job is done.

The first thing to note is whether the changes you have painstakingly implemented are going to stick. There is always the fear of reverting to old habits, even if those old habits were not conducive to your outputs.

You will need to monitor the changes you have implemented, first to see whether they are being followed and secondly to see if they are even working as you hoped.

It is one thing to see something on paper and an entirely different story once it is converted into real life. Things you may not have conceived might be halting your plan from being a success.

Continuous improvement of your process enables the changes you made to last as well as to have the desired effect you hoped for. It is not absurd to realize that there is an issue in the plan.

Once you are monitoring and reviewing the process improvements you may come across some issues. Do not let this deter you. Sit back down with your team and come up with a solution to any holdups or issues that may arise.

Schedule your work with the best calendar apps:

Best Calendar Apps To Supercharge Your Productivity in 2024

Over to You!

After you have your process improvement plan, your process improvement methodology decided and your implementation in the process you are well on your way to the improvement you were seeking.

By following the steps mentioned you will guarantee the enrichments you make to your processes turn into an established practice of your business.

Just remember implementing change in an organization is not always easy but is essential for any growth to occur and should be continuous to enable the growth of your business and its’ outcome.

Good luck!